Popular short course on atomisation for metal powders for the seventeenth time in 2025

Will run again on 18th and 19th September 2025

Posted 05/2025

THE ATOMISING SYSTEMS COURSE ON ATOMIZATION FOR METAL POWDERS

WILL BE HELD ON THE 26TH AND 27TH OF SEPTEMBER 2024

Posted 05/2024

COURSE ON ATOMIZATION

FOR METAL POWDERS

WILL RUN AGAIN ON 28TH AND

29TH SEPTEMBER 2023

Posted 05/2023

- All current atomizer types are covered for most metals, powder types and uses

- Plant design, operation and economics are given high priority

- Courses have been attended by around 400 registrants, covering 16 countries and 5 continents

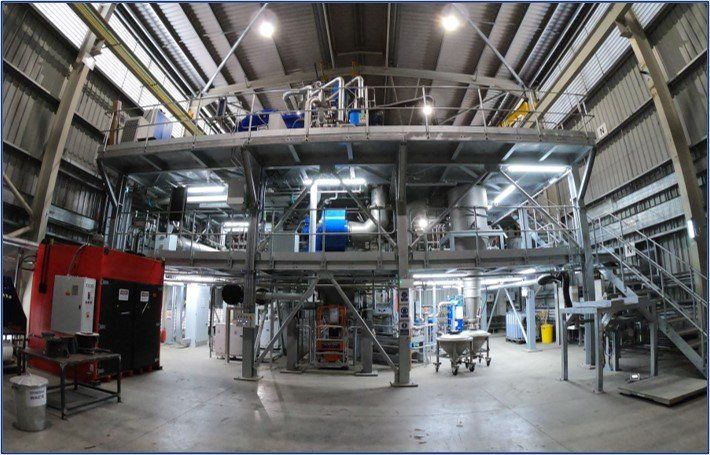

ASL CELEBRATE 30 YEARS OF ATOMISING WITH £1.75 MILLION CAPEX

Posted 04/2023

ATOMISATION FOR METAL POWDERS COURSE MANCHESTER 2022

Posted 05/2022

ASL SUPPLY 250kg VACUUM INDUCTION MELTING ATOMISER TO LIBERTY POWDER METALS

Posted 10/2021

ASL was able to install and commission the plant working within the restrictions imposed by the Covid-19 pandemic. Such restrictions meant that things were not quite as easy to complete as in pre-Covid times.

The fact that ASL operates its own in-house Anti-Satellite gas atomisers on a daily basis (3 shift) was very useful for LPM, as their staff were able to obtain real world experience of production-scale gas atomiser operation prior to the installation and commissioning of their VIGA, allowing them a clearer understanding of the tasks involved and the subtle issues of handling metal powders.

Photograph: Courtesy Liberty Powder Metals Ltd.

The plant, like most systems supplied recently by ASL, is controlled by a PC/PLC system and the ASL control engineer was able to view the system status and operating logs for all parameters while communicating with his opposite number within the system using Google translate.

So, while installation began in early 2020 and the final installation and start-up were badly delayed by the pandemic and by local Covid restrictions, the process overall went quite smoothly, and the client is very happy with the plant’s operation and the product’s quality. The plant’s water atomiser, mated to the client’s 600kg capacity furnace, is now routinely achieving tap-to-tap times below 2 hours. The plant process both steel and ferroalloy powders.

Compared with pre-pandemic practice, the process of start-up was far less stressful for the commissioning engineers, who normally are under severe time pressure and working very long hours on site, due to the need to keep site weeks to a minimum. With remote commissioning, it is possible to take a more relaxed attitude to time, whilst teething issues with equipment interfaces are sorted. It also meant that the excellent communications allowed sharing of information over a much longer time, extending into shake-down and ramping up production, than is feasible with a short site engineer’s visit. With this excellent experience, it is very likely that ASL will consider a hybrid site/remote commissioning strategy for future projects to combine the best points of both options.

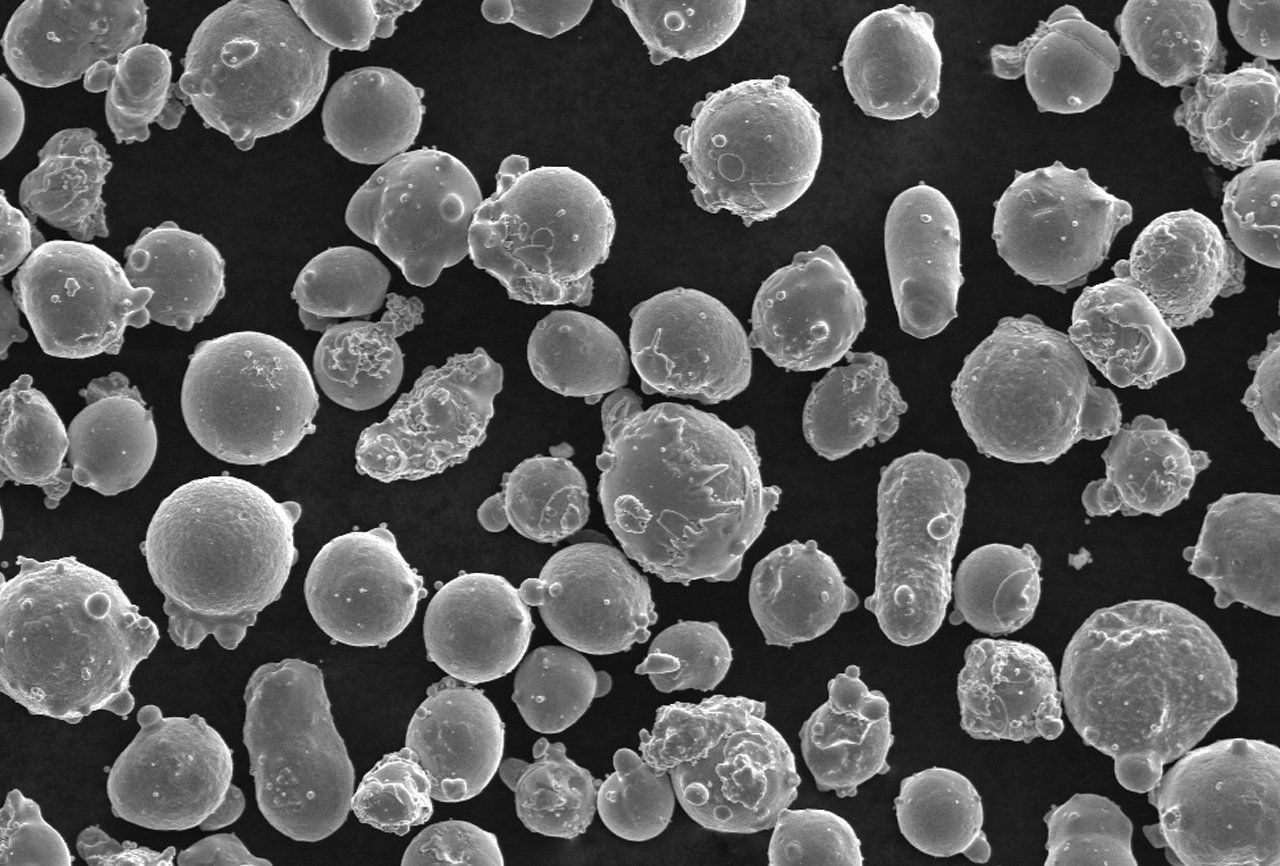

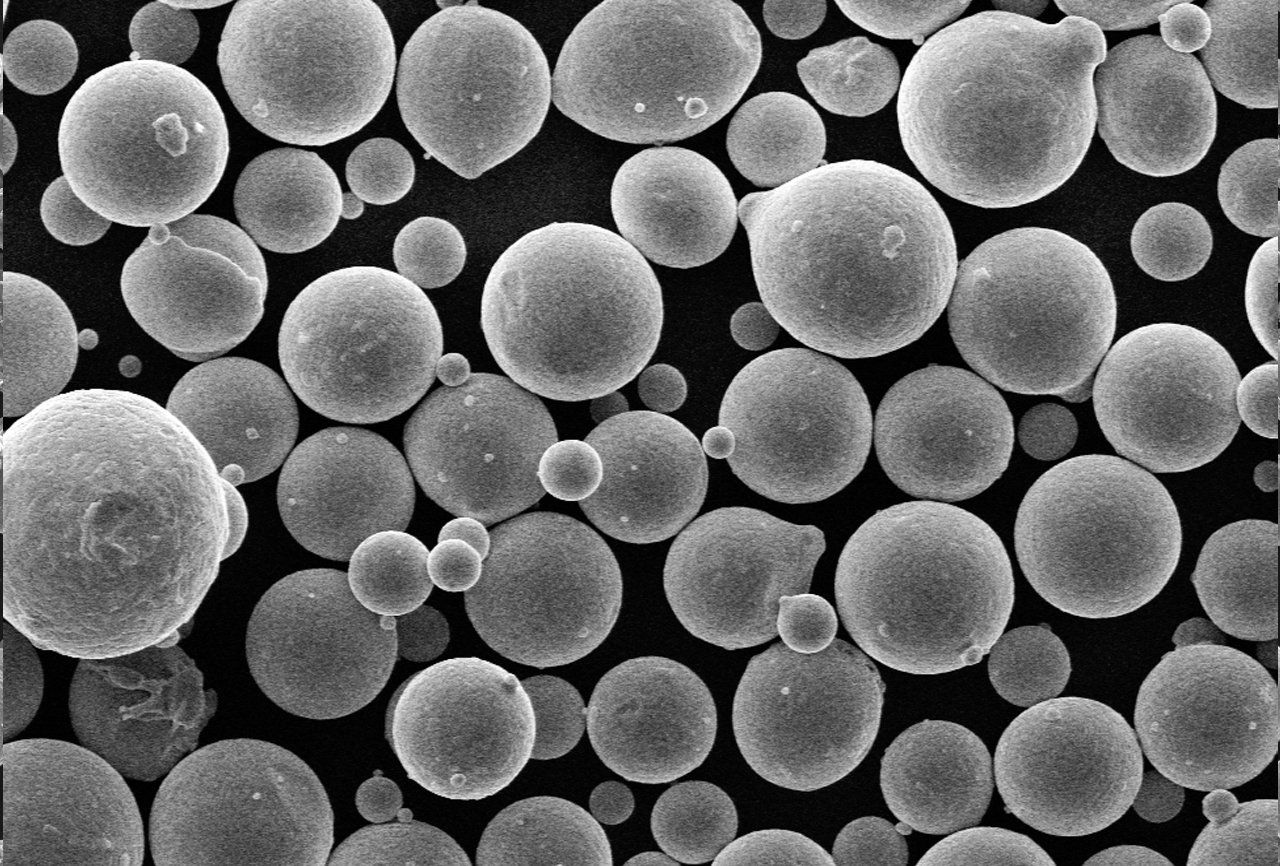

- Chemical composition via ICP-OES and XRF

- Powder oxygen, nitrogen, carbon, and sulphur by Eltra systems

- Particle size by laser diffraction and sieving

- Particle shape by Hall and Carney funnels, density cup, Tap Density, Optical Microscopy

- Compressibility and Green Strength